The Electrical Inspection Report is a document that serves a similar purpose to the Megger Test form. It provides a comprehensive overview of the electrical systems within a facility. Like the Megger Test, it includes detailed measurements and assessments of electrical components to ensure they meet safety standards. The report typically highlights any potential issues and suggests necessary repairs or improvements, ensuring that the electrical systems operate safely and efficiently.

The Circuit Analysis Report is another document that shares similarities with the Megger Test form. This report focuses on evaluating the performance of electrical circuits. It includes data on voltage, current, and resistance, much like the Megger Test. Both documents aim to identify any abnormalities in the circuit's performance, helping to prevent electrical failures and ensuring the reliability of the system.

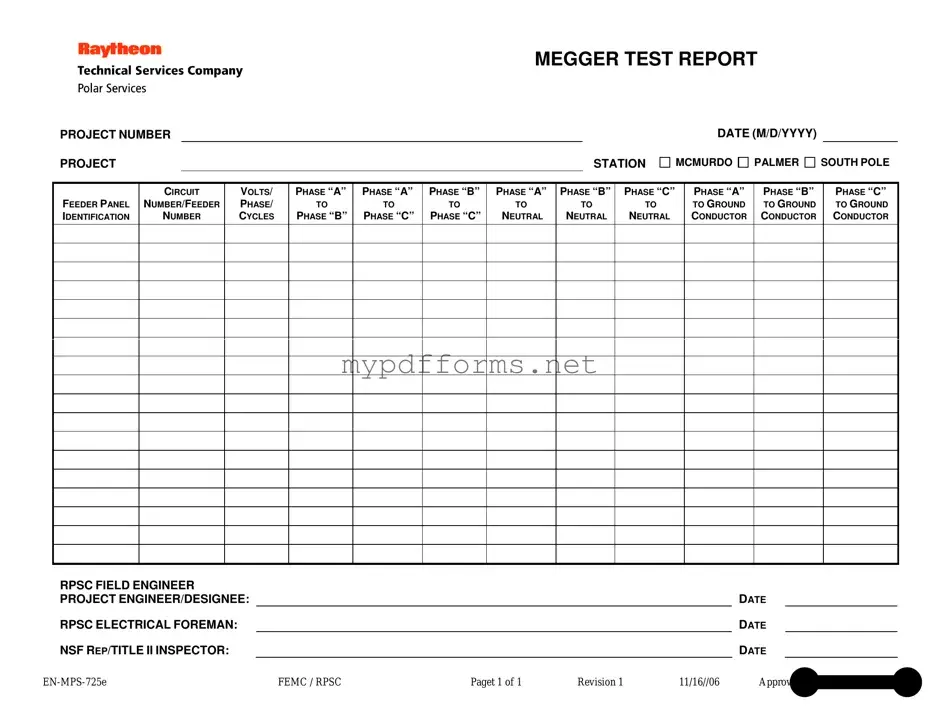

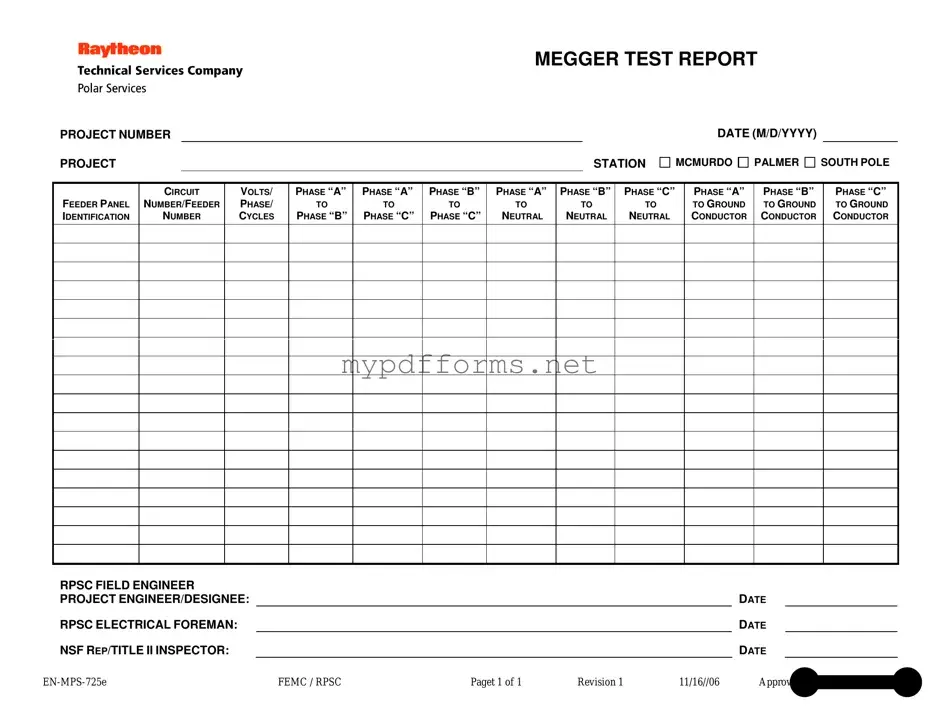

The Insulation Resistance Test Report is closely related to the Megger Test form, as it specifically measures the insulation resistance of electrical components. This report provides critical data on the effectiveness of insulation, which is vital for preventing electrical shocks and equipment damage. Both documents require similar testing procedures and contribute to maintaining electrical safety standards.

The Florida Marriage Application form is an essential document required for couples seeking to obtain a marriage license in the state of Florida. This form captures critical personal information about both individuals, including their names, dates of birth, and residency details. It also includes specific legal stipulations, such as the timeframe within which the marriage must occur and the jurisdictional limitations of the license. For more details, you can visit floridapdfform.com.

The Safety Compliance Checklist is another document that aligns with the objectives of the Megger Test form. This checklist ensures that all electrical installations adhere to safety regulations and standards. While the Megger Test focuses on specific measurements, the checklist provides a broader overview of compliance, including the condition of wiring, grounding, and protective devices.

The Load Testing Report is akin to the Megger Test form in that it evaluates the performance of electrical systems under specific load conditions. This report documents how well a system can handle its rated capacity, similar to how the Megger Test assesses insulation quality. Both reports are essential for ensuring that electrical systems can operate safely under normal and peak conditions.

The Preventive Maintenance Log is another document that shares a connection with the Megger Test form. This log records routine inspections and maintenance performed on electrical systems. It serves as a historical reference, much like the Megger Test report, which documents specific testing results. Both documents are crucial for ensuring ongoing reliability and safety in electrical installations.

The Equipment Calibration Certificate is similar to the Megger Test form in that it verifies the accuracy of testing instruments used in electrical assessments. This certificate ensures that the equipment used for the Megger Test is functioning correctly and provides reliable results. Both documents emphasize the importance of precision in electrical testing and maintenance.

Finally, the Installation Verification Report is related to the Megger Test form as it confirms that electrical installations meet design specifications and safety standards. This report includes various tests and inspections, similar to the Megger Test, to ensure that the installation is safe and functional. Both documents are essential for verifying that electrical systems are installed correctly and can operate safely.