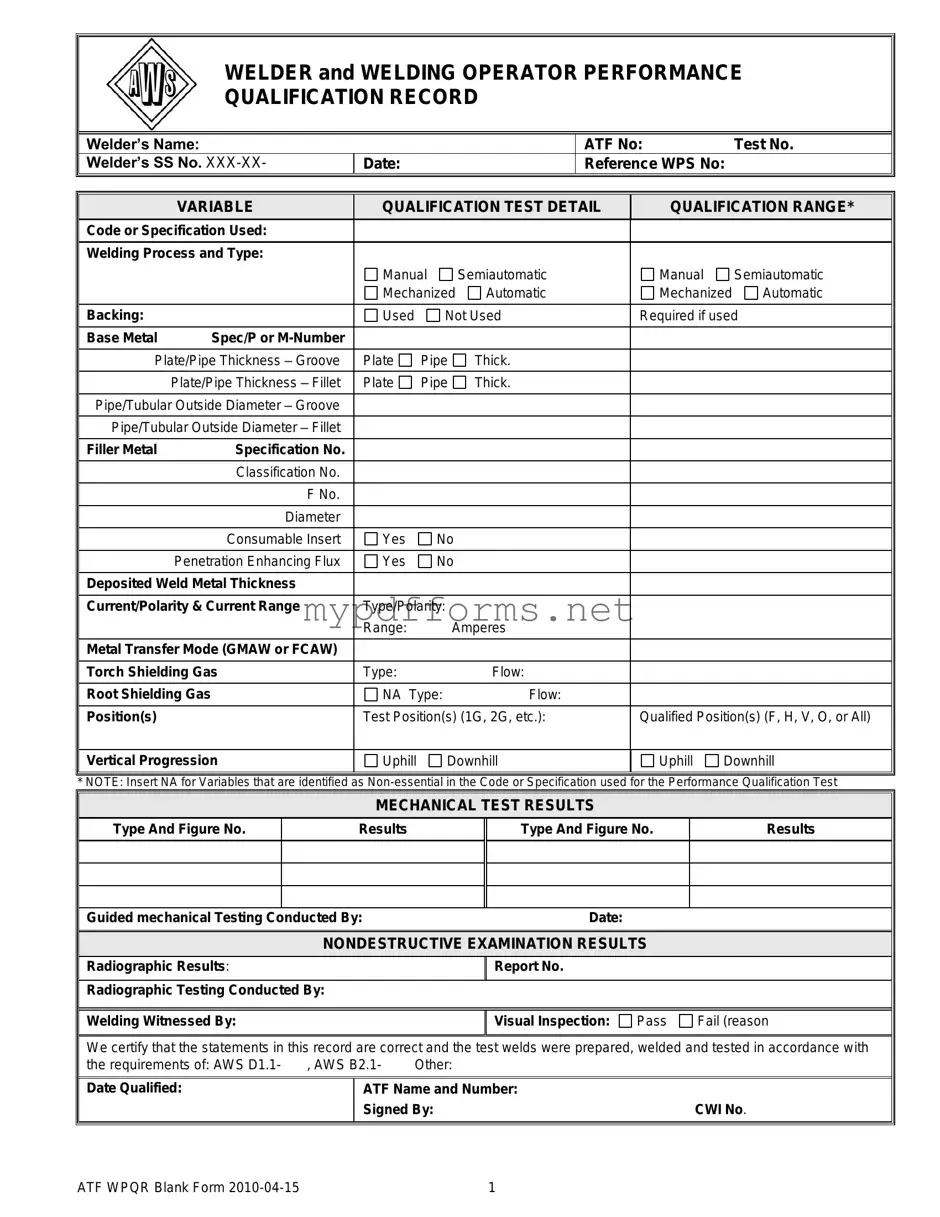

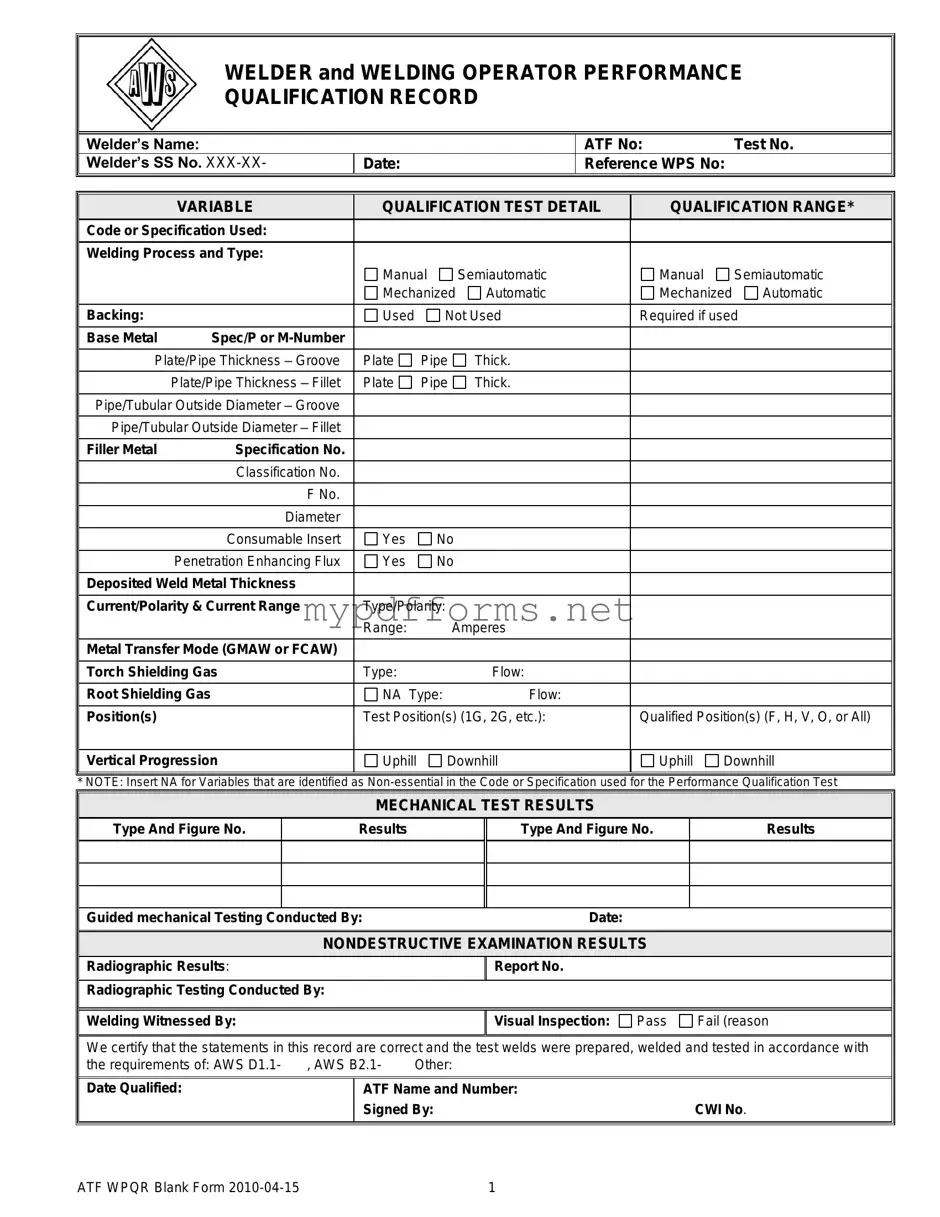

The Welder Performance Qualification Record (WPQR) is similar to the Welding Procedure Specification (WPS). Both documents serve as essential tools in ensuring that welding processes meet industry standards. The WPS outlines the specific parameters and techniques that a welder must follow during a welding operation. Like the WPQR, it includes details such as the type of materials used, welding positions, and the welding process. Together, these documents help maintain quality and consistency in welding projects.

Another related document is the Procedure Qualification Record (PQR). This record demonstrates that a specific welding procedure can produce welds that meet required standards. The PQR includes similar information to the WPQR, such as the materials, welding techniques, and test results. While the WPQR focuses on the qualifications of the welder, the PQR emphasizes the validity of the welding procedure itself, ensuring that both elements work together to achieve quality welds.

The Illinois Bill of Sale form is essential for documenting transactions that involve personal property transfer, and similarly to the welding qualifications that ensure specific operational standards, it solidifies the legitimacy of buyer and seller agreements. For more details on how to create or manage this documentation, you can visit the Illinois Forms resource, which provides necessary templates and guidelines to aid in achieving proper record-keeping.

The Welder Certification Card is also comparable to the WPQR. This card is issued to welders who have successfully completed a certification test. It confirms their ability to perform welding tasks according to specific codes and standards. Like the WPQR, it provides essential information about the welder's qualifications, including their name, certification number, and the types of welding they are certified to perform. Both documents are vital for employers to verify a welder's skills and compliance with industry requirements.

The Non-Destructive Testing (NDT) Report shares similarities with the WPQR in that it provides an assessment of weld integrity without damaging the material. This report details the methods used, such as radiographic or ultrasonic testing, and the results of these evaluations. Like the WPQR, the NDT Report is crucial for ensuring that the welds meet quality standards. Both documents help identify potential issues before they become significant problems, thus enhancing safety and reliability in welding operations.

Lastly, the Inspection Report is akin to the WPQR as it documents the findings of inspections conducted on welds. This report includes information about visual inspections and any non-destructive tests performed. It confirms whether the welds meet the required specifications and standards. Like the WPQR, the Inspection Report is essential for maintaining quality control and ensuring that all welding work is compliant with industry regulations. Both documents work together to ensure the overall integrity of the welding process.